If your facility is not grounded correctly, both your employees and your equipment are at risk. Electricity will find a path to ground, and if a worker is the path of least resistance, they will receive an electrical shock. Depending on the current in the system, the shock could be anywhere from mildly annoying to deadly.

If your facility is not grounded correctly, both your employees and your equipment are at risk. Electricity will find a path to ground, and if a worker is the path of least resistance, they will receive an electrical shock. Depending on the current in the system, the shock could be anywhere from mildly annoying to deadly.

The same theory applies to your equipment. You may find intermittent failures and blown circuits, or you may find equipment completely eliminated due to high voltage levels. Grounding failures come in many forms. You must be familiar with the problem areas and take the appropriate steps to eliminate the dangers.

1. Aluminium wiring

The first item that should be on any electrical safety list is aluminium wiring. If it is present in your facility, it must be removed. Aluminium is reactive and sensitive to temperature changes. While it is used for overhead supply lines, it is not suitable for wiring. When the material heats, it expands. Frequent expansion and contraction loosens connections, which leads to shorts. If aluminium is used to connect to ground, the ground can be broken easily. Do remember that this repair work is a job for professionals. In the United States, aluminium wiring is allowed, it is becoming more popular because of cost. Almost all medium and high voltage distributers use aluminium for cost reasons. At higher voltage levels, the voltage drops over distance.

2. Insufficient or corroded ground rods

Ground, or earth, for a power installation is provided by ground rods driven into the soil. The diameter and length of the rods must meet the requirements for the amount of power being used by the home or facility. The lack of a sufficient grounding rod creates a lack of ground. If the grounding rod is providing resistance, the electricity will locate an easier route.

In many older installations, the metal pipes used for plumbing were used to provide an earth connection. With the increase in the use of plastic piping, this practice is no longer sufficient. Ground rods must also be checked for corrosion. Chemicals in the soil can break down the metal and dissolve it, eliminating the actual connection with an earth ground. This type of inspection should be performed by professionals with the proper equipment.

3. Lack of connections

Everything in an electrical installation may appear to be in working order, but still not be actually providing protection. Loose connections create a resistance to ground. Paint on metal surfaces or insulation left on wires also interfere with a solid, direct connection. Using the wrong type of connectors can also play a role in poor conductivity. All earth bonds must be established according to current building regulations.

4. Lack of ground fault protection

In the United Kingdom, ground fault protection is provided by a Residual-Current Device (RCD). Residual-Current Circuit Breakers (RCCB) are used to protect an entire circuit while RCDs protect individual receptacles and any other devices connected to the load side.

These devices are engineered to immediately stop the flow of current if a leakage is detected. This means that if a person suddenly becomes a better circuit for the power, the device will stop the flow to prevent electrocution. RCD devices, like their GFCI counterparts, are for use in wet locations and outdoor applications.

5. Improper use of extension cords

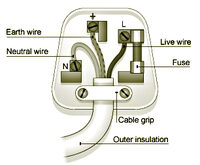

Any electrical cords or exposed wires in a facility must have adequate insulation. If the insulation is damaged, the wire or cord must be replaced. Like U.S. systems, U.K. systems also use a ground prong, or third prong, on cords. This prong cannot be cut off to work in an ungrounded receptacle.

Care must be taken when using cords. They should not be yanked from receptacles or allowed to run across vehicular pathways. If extension cords are frequently required, a new receptacle should be installed.

6. Keep electrical services isolated

Electrical panels, supplies and transformers must be protected to prevent accidental contact. Flammable materials and chemicals must never be stored near any electrical service installations. Electricity and all electrical equipment must also be protected from water exposure.

Have your facility inspected for electrical grounding problems and make sure all of your employees are trained in electrical safety. Workers must be aware of the potential for injury and the location of emergency shut-offs.

Author bio

Bob Sheppard is the Founder, President, and General Manager of Southwest Energy Systems; a NETA (InterNational Electrical Testing Association) accredited testing and engineering firm based primarily out of Phoenix, Arizona.