Workplace safety has become a hot-button issue in every industry. According to the U.S. Department of Labor’s Bureau of Labor Statistics, approximately 3 million non-life threatening injuries occurred in the workplace in 2014. The good news is, that figure is 54,000 less than it was in 2013.

Workplace safety has become a hot-button issue in every industry. According to the U.S. Department of Labor’s Bureau of Labor Statistics, approximately 3 million non-life threatening injuries occurred in the workplace in 2014. The good news is, that figure is 54,000 less than it was in 2013.

We can quote statistics until the cows come home, but the bottom line is, companies still have to work very hard to minimize the risk of injuries to their employees. Three million represents only a small segment of the population, but it is still a large enough number to draw attention to safety issues that are often ignored in many workplaces.

The U.S. Occupational Safety and Health Administration (OSHA) does its part to ensure that safety information is available to every employer in every sector of the American economy, but very often, a few posters and pamphlets in break rooms is not enough to keep everyone safe. Today’s employers have to go above and beyond to ensure employees are safe no matter what type of job they perform. Safety is no longer an issue just in warehouses, construction sites, and other locations where physical labor is performed. Today, employees sitting at desks in offices are at risk of injury as well. It is important that all companies, no matter how large or small, put health and safety first for each and every employee.

Here are seven valuable safety practices all companies should implement – sooner rather than later:

1. Discourage shortcuts; that’s when accidents happen

Everyone wants to get the job done before a deadline, but very often, employees will take shortcuts to ensure their work comes in under-budget and on time. It is important to always be aware of your surroundings no matter where you work, and to make sure you completely understand instructions and guidelines before commencing work on a project. Taking shortcuts can not only result in shoddy work, it can also mean putting yourself at risk for an accident. Supervisors should re-think assignments in order to prevent injuries. Make sure the right person is chosen for the job and that the time frame is manageable, not one that will leave an individual or team scrambling against an unrealistic deadline.

2. Encourage safety while travelling

According to OSHA, workplace vehicular accidents cost employers about $60 billion per year. If employees are driving company-owned vehicles, it is imperative that those vehicles be inspected regularly, and repaired or replaced when necessary. Inspections should take place on a monthly basis and items including brake lights, turning signals, and tire pressure should always be checked. Attention to even the smallest details goes a long way when it comes to preventing car accidents.

3. Mind the weather

Inclement weather conditions can make commuting to work or working outdoors quite challenging. All businesses, regardless of industry should be mindful of weather forecasts to ensure that employees don’t put themselves in harm’s way attempting to get to the office, or when working outdoors. No job is worth putting yourself at risk during severe weather conditions; keep an eye on the forecast for significant snow and rainstorms, as well as other seasonal weather events like tornadoes, hurricanes, and extreme heat and cold. Moreover, every company should train its employees in disaster preparedness in the event that they get stuck at work during a natural or manmade disaster.

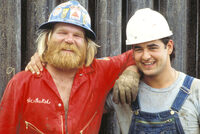

4. Always wear necessary PPE

The wearing of PPE (Personal Protective Equipment) should be enforced no matter how small the apparent risk of injury. Items like goggles, gloves, face protection, and hard hats should always be worn in places where you could be injured by wayward particles, dangerous substances, or falling items from warehouse shelves. Moreover, it is important to remember to protect ears with ear plugs in noisy spaces, and feet with appropriate footwear in places where floors could be slippery, or items could be dropped.

5. Keep it clean

Nothing will cause accidents faster than an untidy workspace. Everything from a messy desk to an industrial space cluttered with tools or dangerous machinery could cause injuries. Employees should be encouraged to be mindful of the state of their personal spaces, taking time to organize papers, put away tools and other items that are not currently being used, and ensure there are no other hazards that could cause any mishaps. Things like slips-and-trips, and fires commonly occur when routine “housekeeping” isn’t performed regularly.

6. Foster a culture of safety

Many larger companies can spend serious dollars on consultants and other professionals to teach their employees about workplace safety training. Fortunately, the internet and social media has made it easier for smaller organizations to provide the same instructions to their employees. YouTube, Facebook, Twitter, and other popular social media destinations can help any size company foster a culture of safety, as well as share ideas about how to minimize, and hopefully eliminate workplace injuries.

7. Keep it simple

The most important aspect of achieving workplace safety is to come up with a plan that it simple and easy to follow. Make safety the responsibility of each and every employee, regardless of the jobs they perform. Established safety practices that are enforced across the board will avoid confusion, and make it clear that everyone should have a hand in keeping one another safe. When management and employees work together to achieve a common goal, workplace safety will never be compromised.

Author Bio:

Kathy Amato is the Director of Marketing at Coggno.com, a website that aggregates online training courses and also offers a free Learning Management System.